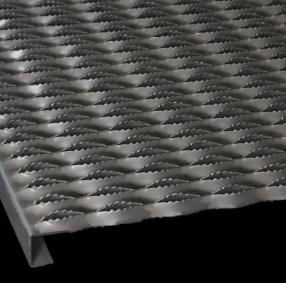

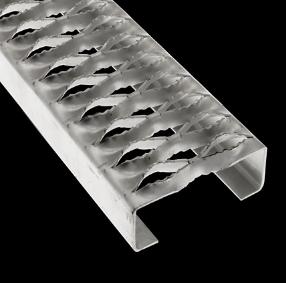

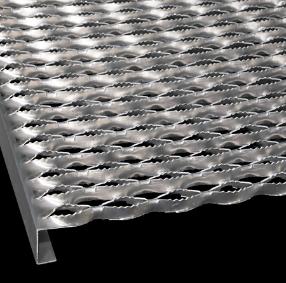

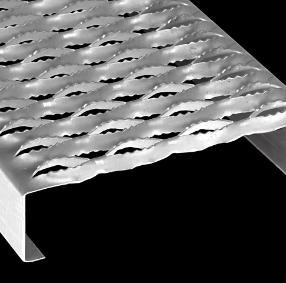

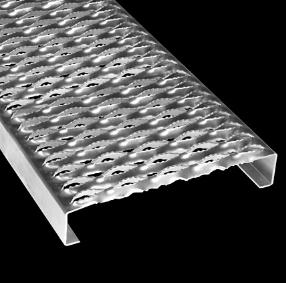

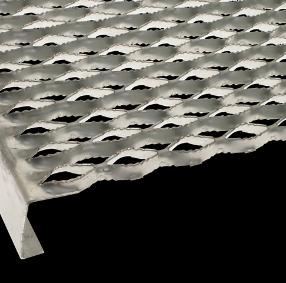

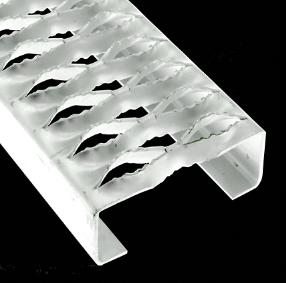

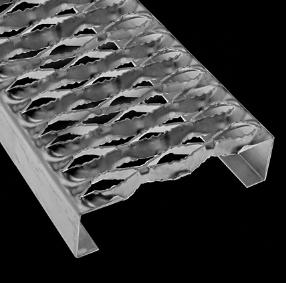

Gach bliadhna, bidh tubaistean gnìomhachais a ’tachairt a chosgas milleanan dolar ann an uairean duine caillte agus cinneasachadh. Tha casg air mòran de na tubaistean sin agus tha iad a ’dol bho bhith a’ tuiteam, a ’tuisleachadh thairis air sprùilleach, no a’ sleamhnachadh air uachdar fliuch no uaine. Tha Direct Metals a ’tabhann grating meatailt sàbhailteachd Yunde agus staidhrichean a chuidicheas le bhith a’ lughdachadh ìrean tubaist le bhith a ’toirt uachdar obrach coiseachd nas sàbhailte na toradh grating meatailt sam bith eile air a’ mhargaidh. Tha uachdar serrated aig na feansaichean làr sàbhailteachd meatailt agus na staidhrichean againn a bheir seachad an dìon as àirde anns a h-uile suidheachadh agus a h-uile taobh.

Buannachdan Grating Sàbhailteachd:

- Tha pàtran fosgailte daoimean a ’ceadachadh drèanadh de fhliuchas, eabar, sgoltagan, agus sprùilleach eile a dh’ adhbhraicheas tubaist tro grating làr agus staidhrichean staidhre

- Raon leudan bho 4-3 / 4 ″ gu 36 ″

- bidh slighean coiseachd meatailt sàbhailteachd a ’coinneachadh ri riatanasan OSHA airson bùird òrdag air structar àrdaichte

- Tha e ri fhaighinn ann an cunbhalach, dleasdanas trom, slighe coiseachd agus staidhrichean staidhre

- Ri fhaighinn ann an stàilinn ghalbhanaichte, stàilinn gualain, stàilinn gun staoin, agus alùmanum

Thathas a ’cleachdadh staidhrichean staidhre agus grating sàbhailteachd meatailt gus slighean coiseachd meatailt, flooring sàbhailteachd stàilinn, agus staidhrichean staidhre resistant slip a chruthachadh. Tha coileanadh àrd neart gu cuideam aig na plancaichean grating meatailt sin, a nì cinnteach gu bheil comas luchdan àrd agus beatha fhada. Tha na staidhrichean staidhre resistant slip againn, ris an canar Grip Strut ™ grating, air uachdar serrated a bhios a ’greimeachadh air bonn bhrògan obrach, a’ lughdachadh thubaistean san àite obrach agus a dh ’fhaodadh staidhrichean a dhèanamh nas sàbhailte.

| Openingtype | Grip Strut | Alùmanum | Galvanised | Stàilinn gualain | |||||||||||

| doimhneachd | Gauge | Gauge | Gauge | ||||||||||||

| 9 | 10 | 11 | 12 | 14 | 9 | 10 | 11 | 12 | 14 | 9 | 10 | 12 | 14 | ||

| 2-Daoimean | 1-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 2-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 3 ″ | ● | ● | ● | ● | ● | ||||||||||

| 4 ″ | ● | ● | ● | ● | |||||||||||

| 4-Daoimean | 1-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 2-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 3 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 4 ″ | ● | ● | ● | ● | |||||||||||

| 5-Daoimean | 1-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 2-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 3 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 4 ″ | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 6-Daoimean | 1-1 / 2 ″ | ● | ● | ● | ● | ● | |||||||||

| 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 2-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 3 ″ | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 4 ″ | ● | ● | ● | ● | ● | ● | |||||||||

| 8-Daoimean | 1-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 2-1 / 2 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 3 ″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 4 ″ | ● | ● | ● | ● | ● | ● | ● | ● | |||||||